Meanwhile, the silica gel is also a kind of weak acid cation exchanger with the silanol group on the surface being able to release weakly acidic hydrogen ions. Silica gel is an acidic adsorbent, being suitable for the chromatography of neutral or acidic components. Therefore, the activation of the silica gel should not proceed at higher temperatures (generally at above 170 ℃, there will be a small amount of bound-water lost). Even water treatment can’t restore its adsorption activity.

When the temperature rises to 500 ℃, the silanols on the silica surface can also undergo dehydration and condensation to convert into a siloxane bond, thus losing the activity of absorbing water through the hydrogen bonds, thereby no longer there having the nature of the adsorbent.

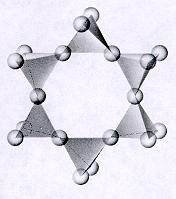

For the activation of the silica gel, when silica gel is heated to 100 ~ 110 ℃, the hydrogen bond-absorbed water molecule on the silica gel surface can be removed. If the water absorption capacity exceeds 17%, the absorption force is too weak to be used as an adsorbent, but can be used as the supporting agent in the partition chromatography. Silanol group can absorb the water molecule through the formation of hydrogen bond so the absorption force of silica gel will decrease with the increase of the absorbed moisture. The absorption strength of the gel silica is dependent on the content of the silanol. The molecule contains the cross-link structure of siloxane (-Si-O-Si), while there are a lot of silanol groups on the surface of the particle. Discoloration gel is mainly used to indicate the relative humidity of airtight packaging, precision instruments and the inner space of instrument as well as being used for the moistureproof maintenance of precision instrumentation.Ĭhromatography-purpose silica gel is a kind of porous material, being able to be represented by the formula SiO2

Coarse-pore gel silica is mainly used to process the macromolecular protein contained in the beer as well as the drying of gas and liquid and defogging as well as dehumidification of gas upon high humidity, as the catalyst and catalyst carrier in the petrochemical industry. Pore silica gel is mainly used for the drying and purification of gas, the dehydration and purification of organic product, also used as a supported carrier. The textile industry uses it as sizing agent. Gel silica is mainly used for gas absorption or drying, liquid dehydration and liquid chromatography, also used as catalysts or catalyst carrier. General industrial silica gel has a mechanical strength of 85 to 95%, water content being below 2% and the moisture absorption rate of 25 to 30%. The silica gel can be manufactured through the reaction between water glass and sulfuric acid, and further gelling, washing, desalting, amidation, drying and screening. The pink silica gel has no absorbent capacity, but after thermal dehydration, it will have its color return back to blue and get its absorbent capacity restored. According the change of the color during dehydration and hydration of cobalt chloride, we can know moisture absorption condition of the silica gel. However, after absorbing water, the hydrated cobalt chloride will exhibit pink color with returning back to blue after drying. There is another kind of discoloration gel silica containing cobalt chloride with anhydrous cobalt chloride exhibiting blue color. According to the pore size, it can be divided into the fine-pore silica gel (with average pore size of less than 1.5 ~ 2.0nm) and coarse pore gel silica (with average pore size of greater than 4.0 ~ 5.0nm). The commercially available solid gel silica has spherical and irregular, two kinds of shapes. Silica gel can’t be dissolve in water, not soluble in other solvents except hydrofluoric acid and strong alkali. Therefore, it has strong absorption capability on the liquid or gas. The specific surface area per g silica can reach above 450 m2. Silica is a highly active, porous material with the internal surface area being large. nH2O, appears as slightly transparent white solid substance.

0 kommentar(er)

0 kommentar(er)